Fiber Reinforced Polymer Market Growth at 8.1% CAGR During 2024-2031, Fueled by Asia Pacific's Dominant 43% Share

Fiber Reinforced Polymer Market surges with lightweight, corrosion-resistant composites revolutionizing automotive, aerospace, construction & renewables.”

AUSTIN, TX, UNITED STATES, December 1, 2025 /EINPresswire.com/ -- According to DataM Intelligence, the Global Fiber Reinforced Polymer Market is predicted to grow at a robust CAGR of 8.1% during the forecast period 2024–2031.— DataM Intelligence

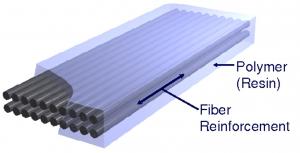

The growing demand for lightweight, high-strength materials in industries such as aerospace, automotive, construction, and wind energy is a key driver of this market growth. Fiber reinforced polymers provide enhanced mechanical properties, corrosion resistance, and design flexibility, making them ideal for replacing traditional metals and composites.

Advancements in manufacturing technologies, including automated fiber placement and 3D printing, along with increasing environmental regulations promoting durable and sustainable materials, are accelerating the adoption of fiber reinforced polymers worldwide. These factors collectively are paving the way for significant expansion of the market across developed and emerging economies.

Download your exclusive sample report today: (corporate email gets priority access): https://www.datamintelligence.com/download-sample/fiber-reinforced-polymer-market

Key Industry Developments:

- Owens Corning launched a new range of high-strength fiber reinforced polymer composites specifically for wind energy and aerospace sectors, enhancing performance and durability.

- Toray Industries unveiled advanced FRP composites with improved fire resistance tailored for electric vehicles and aerospace applications, responding to industry safety standards.

- Owens Corning's India business acquisition confirmed: In September 2025, the Competition Commission of India (CCI) formally approved the acquisition of Owens Corning's India business by Triumph Composites and Quartz Fibre. This follows Owens Corning's larger strategic move to sell its global glass reinforcements business, focusing on core building and construction materials

- Hexcel and Flying Whales collaborate on airships: In June 2025, Flying Whales and Hexcel Corporation partnered to develop advanced airship structures using Hexcel's cost-efficient and high-performance HexTow IMA Carbon Fiber.

Market Growth Drivers

-The growing demand for lightweight and high-strength materials in transportation, especially in aerospace and automotive sectors, is a major driver of the Fiber Reinforced Polymer (FRP) market. FRP composites help improve fuel efficiency and vehicle performance by reducing weight without compromising strength, particularly benefiting the rising electric vehicle segment. In aerospace, these materials enable the production of fuel-efficient, low-emission aircraft components, driving significant market growth.

-Rapid urbanization, population growth, and increasing infrastructure investments globally are accelerating the adoption of FRP materials in construction. These composites offer superior corrosion resistance, durability, and design flexibility compared to traditional materials, creating demand in building structures, bridges, and retrofitting projects. Government initiatives promoting sustainable and resilient infrastructure further support FRP utilization in construction.

-Advancements in manufacturing technologies and the expanding renewable energy sector also fuel market expansion. Automated fiber placement, advanced polymer matrices, and 3D printing techniques enhance FRP production efficiency and customization. Moreover, FRP composites play a crucial role in wind turbine blades and other renewable energy infrastructure, aligning with global sustainability goals and increasing clean energy investments.

Segmentation Analysis

-By Type

The market is segmented into Glass Fiber Reinforced, Carbon Fiber Reinforced, Basalt Fiber Reinforced, Aramid Fiber Reinforced, and Others. Glass Fiber Reinforced dominates due to its cost-effectiveness, high strength-to-weight ratio, and widespread use in construction, automotive, and marine applications. Carbon Fiber Reinforced grows rapidly in aerospace and high-performance automotive sectors for superior stiffness and lightweight properties. Basalt Fiber Reinforced gains traction for corrosion resistance in infrastructure, while Aramid Fiber Reinforced excels in defense and ballistic applications; Others include natural and hybrid fibers for specialized uses.

-By End-User

By end-user, the market covers Electronics, Automotive, Construction, Defense, and Others. Automotive leads with demand for lightweight components to enhance fuel efficiency and electric vehicle range. Construction utilizes FRP for corrosion-resistant rebar, panels, and structural elements in bridges and buildings. Defense applies high-strength composites in armor and aircraft; Electronics employs them in housings and PCBs for durability. Others encompass aerospace, wind energy, and marine sectors leveraging FRP's design flexibility and performance advantages.

Buy Now & Unlock 360° Market Intelligence: https://www.datamintelligence.com/buy-now-page?report=fiber-reinforced-polymer-market

Regional Insights:

-The Asia Pacific region holds the largest share in the Fiber Reinforced Polymer (FRP) market, with a market share of approximately 43.59% in 2023. The region's dominance is driven by strong growth in the automotive and construction industries, with China being a major producer of automobiles, influencing the increased adoption of FRP composites in various applications.

-North America follows with a market share of about 33.2% in 2024, led by the United States, which accounts for around 71% of the region’s FRP production. The strong presence of aerospace, automotive, and defense industries underpins North America's market leadership, supported by substantial investments in infrastructure modernization, clean energy manufacturing, and federal fuel efficiency standards.

-Europe holds a significant position as well, with the market expected to exhibit the highest compound annual growth rate in the forecast period due to increasing demand in the transport and construction sectors. The region's growing focus on sustainable infrastructure and engineering applications contributes to this expansion.

Competitive Landscape:

-The Fiber Reinforced Polymer Market is competitive with key players like Owens Corning, Miyabifrp Corporate, Mitsubishi Chemical Corporation, B&B FRP Manufacturing, Saint Gobain, Nippon Sheet Glass, SCL Carbon, Aksaca, Glassonweb, AGC Inc, Guardian Industries, Hengshui Jiubo Composites Co. Ltd, Composite & Metal Products USA Inc., Veplas d.d., and others leading the space. These companies focus on strategic partnerships, product innovation, and expanding high-performance FRP composites for construction, automotive, aerospace, and wind energy applications.

-Established firms such as Owens Corning and Mitsubishi Chemical Corporation drive market leadership through advanced glass and carbon fiber reinforcements, emphasizing corrosion-resistant and lightweight solutions. Innovations in sustainable, recyclable FRP materials and cost-effective manufacturing processes are key priorities amid rising demand for EVs and infrastructure projects.

-Collaborations with automotive OEMs and ongoing R&D in thermoplastic matrices enhance durability and recyclability, positioning these firms as trusted providers in a market growing at over 5% CAGR through 2030.

Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/fiber-reinforced-polymer-market

Conclusion:

The Fiber Reinforced Polymer (FRP) Market is poised for significant growth, driven by increasing demand across industries such as automotive, aerospace, and construction. Its advantages of lightweight, high strength, and corrosion resistance make it essential for modern engineering needs. With ongoing advancements and sustainability focus, the FRP market is set to reshape material applications globally by 2031.

Related Reports:

1. 3D Printing Plastics Market - expected to reach at a CAGR of 21.2% during the forecasting period 2024-2031

2. Metal Injection Molding Market - projected to grow at a CAGR of 8.0% during the forecast period (2024-2031)

Sai Kiran

DataM Intelligence 4market Research LLP

+1 877-441-4866

email us here

Visit us on social media:

LinkedIn

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.