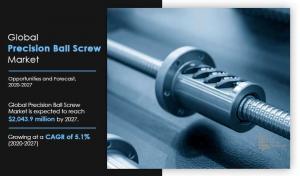

Precision Ball Screw Market: Advancing Motion Control for Precision Applications & Analysis By 2031

precision ball screw market size was valued at $1,571.0 million in 2019, and is projected to reach $2,043.9 million by 2027

PORTLAND, UNITED STATES, May 31, 2023/EINPresswire.com/ -- In the world of precision motion control, precision ball screws serve as key components in a wide range of applications. These mechanical devices convert rotational motion into linear motion with high accuracy and efficiency. From aerospace and automotive industries to robotics and manufacturing, precision ball screws play a crucial role in enabling precise movement and positioning. In this blog, we will explore the precision ball screw market, its significance, key applications, advancements, and factors driving its growth.

global precision ball screw market size was valued at $1,571.0 million in 2019, and is projected to reach $2,043.9 million by 2027, registering a CAGR of 5.1%.

Download PDF Sample: https://www.alliedmarketresearch.com/request-sample/3245

The Significance of Precision Ball Screws: Precision ball screws are critical for applications that require precise linear motion control. Here are some reasons why precision ball screws are significant:

High Precision and Accuracy: Precision ball screws are designed to deliver exceptional accuracy and repeatability in linear motion. With minimal backlash and high rigidity, they ensure precise positioning and motion control in various precision applications.

Efficient Power Transmission: These mechanical devices efficiently convert rotary motion into linear motion, resulting in energy-efficient operation. Compared to alternative methods, precision ball screws offer high mechanical efficiency, reducing power consumption and heat generation.

Smooth and Silent Operation: Precision ball screws provide smooth and quiet operation, making them suitable for applications where noise reduction is important. Their design minimizes vibration and ensures a stable and reliable motion profile.

Long Service Life: With proper maintenance and lubrication, precision ball screws offer a long service life. Their robust construction and high-quality materials withstand heavy loads, harsh environments, and frequent usage, ensuring durability and reliability.

Key Applications of Precision Ball Screws: Precision ball screws find applications in various industries that demand precise linear motion control. Here are some key application areas:

Industrial Automation and Robotics: Precision ball screws are widely used in industrial automation and robotics, enabling precise positioning and movement in assembly lines, CNC machines, pick-and-place robots, and other automated systems.

Inquire Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/3245

Aerospace and Defense: In the aerospace and defense sectors, precision ball screws are crucial for flight control systems, actuation systems, weapon systems, and satellite positioning mechanisms. They ensure precise control in critical operations, enhancing safety and performance.

Automotive Manufacturing: Precision ball screws are employed in automotive manufacturing processes, including body assembly, painting robots, and engine assembly lines. They facilitate accurate movement and positioning of components, ensuring efficiency and quality in production.

Medical Equipment: Precision ball screws are utilized in medical equipment such as surgical robots, imaging systems, and diagnostic devices. They enable precise motion control for surgical procedures, patient positioning, and imaging accuracy.

Advancements and Market Growth: The precision ball screw market continues to witness advancements that enhance performance and broaden application possibilities. Some notable trends include:

Miniaturization: With the demand for compact and lightweight systems, miniaturized precision ball screws are gaining popularity. These smaller-sized screws offer high precision and enable precise linear motion in constrained spaces, opening new avenues for application development.

High-Speed Capabilities: Advancements in manufacturing techniques and materials have led to precision ball screws that can operate at higher speeds without compromising accuracy. This allows for faster production cycles and improved productivity in various industries.

Integration of Smart Features: The integration of smart technologies, such as sensors and feedback systems, enables real-time monitoring and control of precision ball screws. These smart ball screws offer enhanced precision, self-correction capabilities, and remote monitoring, contributing to efficient and reliable motion control.

Growing Industrial Automation: The increasing adoption of automation in industries, driven by the need for improved productivity and efficiency, fuels the demand for precision ball screws. As more industries embrace automation, the market for precision ball screws is expected to expand.

Conclusion: The precision ball screw market plays a crucial role in enabling precise linear motion control across various industries. From industrial automation and robotics to aerospace and medical equipment, these mechanical devices ensure accurate positioning, efficiency, and durability. With advancements in miniaturization, high-speed capabilities, smart features, and the growing trend of industrial automation, the precision ball screw market is poised for growth. As industries continue to demand precise motion control in their operations, precision ball screws will remain indispensable components, advancing technology and driving innovation in precision applications.

David Correa

Allied Analytics LLP

+ + 1-800-792-5285

email us here