Fluoramics introduces HinderRUST® HV500

Industrial Grade Black Liquid-to-Wax Metal Protection

We’re excited about HinderRUST HV500 as a corrosion control option as it pairs a very robust rust-stopping chemistry with an eye-pleasing black coating. The possibilities for usage are tremendous.”

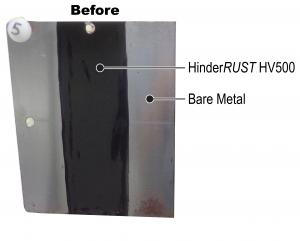

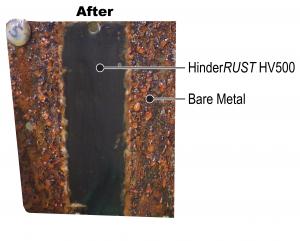

WINONA, MN, USA, June 23, 2022 /EINPresswire.com/ -- Fluoramics, long known for its HinderRUST line of rust stoppers, now offers HinderRUST HV500, an industrial grade non-drying blackened version of HinderRUST. HV500 is engineered to provide even stronger rust control while attractively covering over existing rust. This makes it perfect for use on no-touch areas of vehicles, industrial equipment, wrought iron fences, steel cables and wire ropes.— Gregg Reick, Fluoramics’ President and Chief Chemical Engineer

Fluoramics’ unique Liquid-to-Wax formula means that it is easy to apply in a liquid state by paintbrush, roller or sprayer. It then slowly thickens to a wax-like surface protectant, providing a strong barrier against moisture and oxygen. Use it on bare and rusted metal with no surface prep required. Because it is engineered with a UV-resistant black color, the coating stays a rich black and covers over existing rust while protecting against new corrosion.

Unlike most other rust inhibitors, HinderRUST is based on engineered PTFE chemistry that makes it an incredibly effective rust stopper. This compound is surface active because through a chemical process known as adsorption, it actually spreads across the surface of metal and forms a molecular adhesion to the surface, The process creates a film of HinderRUST on the surface of the metal which make it much more difficult to wash off.

HinderRUST HV500 is the most robust corrosion stopper in Fluoramics' line of rust inhibitors PLUS it is black in color to cover over any existing rust while protecting against new corrosion.

"We’re excited about HinderRUST HV500 as a corrosion control option as it pairs a very robust rust-stopping chemistry with an eye-pleasing black coating. The possibilities for usage are tremendous,” said Gregg Reick, Fluoramics’ President and Chief Chemical Engineer.

All HinderRUST products are solvent-free and non-hazardous which means they are safe to use everywhere and will not evaporate over time. The chemistry is both water-displacing and self-repairing. It remains mobile and fills voids created by nicks, scratches, or dents. Like all maintenance products, it should be reapplied annually or as needed to maintain the barrier against corrosion.

HinderRUST HV500 is available in 32 fl. oz. (part 9643361), 119 fl. oz. (part 9643363) and 640 fl. oz. (part 9643365) containers.

Fluoramics, Inc. is a leading manufacturer of sealants, greases, lubricants, and rust inhibitors, all of which are engineered PTFE solutions. Founded in 1967, the company is based in Winona, Minnesota, and proudly manufactures all its products in the United States. To learn more about Fluoramics’ products, please visit the company's website at www.fluoramics.com.

Patti Reick

Fluoramics, Inc.

+1 507-205-9216

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn