Vermont Manufacturing Company To Help Fight COVID-19

SMALL VERMONT MANUFACTURING COMPANY SHIFTS ITS FOCUS TO HELP DECONTAMINATE THOUSANDS OF N95 MASKS AND OTHER PPE.

BARRE, VERMONT, UNITED STATES, April 9, 2020 /EINPresswire.com/ -- FOR IMMEDIATE RELEASE

iDRY Systems

Jim Parker, President

(802) 327-7592

marketing@idrysystems.com

http://idryandsterilize.com

SMALL VERMONT MANUFACTURING COMPANY SHIFTS ITS FOCUS TO HELP DECONTAMINATE THOUSANDS OF N95 MASKS AND OTHER PPE.

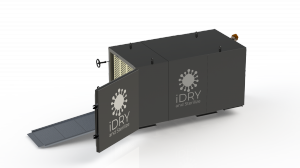

iDRY Systems, producers of drying technology for the wood, hemp, and food markets wants to use its products to address the N95 shortage by decontaminating and sterilizing thousands of masks and other PPE in just hours with the introduction of the iDRY and Sterilize line.

Barre, VT, APRIL 7, 2020; iDRY Systems, the leader in vacuum drying technology, is retrofitting its drying technology to address the growing demand for sterilized N95 masks due to the recent shortage of products available to protect against exposure to coronavirus. Recent studies and reports show the growing need for reusing masks, and iDRY may be a solution for first responders, hospitals, and essential businesses.

Research conducted on the effects of heat to kill the coronavirus on N95 masks suggests that the iDRY technology, which can heat thousands of masks in hours, may be an effective tool to help essential workers.

Jim Parker, president of the family-run iDRY Systems, wants a way to contribute solutions during this time and knows his technology could help with the introduction of the iDRY and Sterilize product line. There is a clear shortage of N95 masks and other personal protective equipment that needs to be addressed. The CDC is now saying “FFR (filtering facepiece respirator) decontamination and reuse may need to be considered as a crisis capacity strategy to ensure continued availability.”

iDRY and Sterilize is neither approved by the FDA nor recognized by the CDC. Jim Parker adds, “As an entrepreneur and owner of a small business, I admit I don’t have all the answers. However, I do know that our technology can reach the recommended heat and time that experts are saying is needed to kill coronavirus on the masks that our healthcare workers need to save lives. We hope our technology can help provide more healthcare workers with clean masks and have a positive impact on the containment of this virus."

iDRY is looking for partners and collaborators from the scientific community, health systems, and state or federal governments to make this technology available.

To learn more about iDRY and Sterilize products, contact President Jim Parker: (802) 327-7592, visit http://idryandsterilize.com or email marketing@idrysystems.com.

Jim Parker

iDRY Systems

+1 802-327-7592

email us here

Visit us on social media:

Facebook

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.