Titanium Powder Market Soars Across APAC, Europe, USA & KSA - Global Value to Quadruple USD 6.8 Billion by 2035

Advancements in additive manufacturing, aerospace innovation, and medical-grade titanium applications fuel 14.8% CAGR growth worldwide.

NEWARK, DE, UNITED STATES, November 12, 2025 /EINPresswire.com/ -- Future Market Insights (FMI) projects that the global titanium powder market will expand from USD 1.7 billion in 2025 to nearly USD 6.8 billion by 2035, registering a compound annual growth rate (CAGR) of 14.8%. The surge is being driven by aerospace modernization, medical 3D printing, and the industrial shift toward lightweight, corrosion-resistant materials.

As cost reductions in plasma atomization and aerospace-grade recycling improve feedstock efficiency, titanium powder is emerging as a strategic material across multiple high-performance sectors, FMI’s latest report indicates.

Global Market Overview

Titanium powder, prized for its strength-to-weight ratio and corrosion resistance, is witnessing a significant expansion in high-precision industries. FMI’s analysis reveals that aerospace and defense applications will dominate demand, capturing nearly 52% of global revenues by 2025, followed by automotive (20–25%), medical (15%), and industrial uses (10%).

The rise of additive manufacturing technologies—especially powder bed fusion and directed energy deposition—is revolutionizing component fabrication, cutting material waste by up to 40%, and shortening lead times across OEM supply chains.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-23000

Segmental Insights

- By Product: Alloyed titanium powder remains the leading product type, accounting for 54.6% of total market share in 2025. Its superior tensile strength, fatigue resistance, and adaptability for 3D printing make it indispensable for aerospace turbines and defense components.

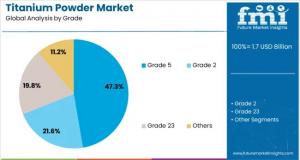

- By Grade: Grade 5 (Ti-6Al-4V) leads with 47.3% of market share due to its biocompatibility and machinability, ensuring consistent adoption in medical implants and marine engineering.

- By Application: Aerospace and defense remain the cornerstone segments, with titanium powder enabling lightweight aircraft structures, propulsion systems, and defense-grade armor.

Regional Outlook

Asia-Pacific (APAC) — Fastest Growing Region

APAC continues to be the epicenter of titanium powder production and consumption.

- China is forecasted to record a CAGR of 20.0% (2025–2035), propelled by domestic aerospace programs and metal 3D printing for jet components and defense hardware. Advanced hydride-dehydride and gas atomization processes are expanding local capacity, enabling self-reliance in high-purity powders.

- India, following closely with an 18.5% CAGR, is leveraging titanium powder for biomedical implants, defense-grade fasteners, and aerospace brackets, as new atomization units and metallurgical hubs take shape.

Together, China and India represent more than one-third of global titanium powder consumption by 2035, reinforcing Asia-Pacific’s position as the fastest-growing regional cluster in the global titanium ecosystem.

Europe — Engineering Excellence and Advanced Manufacturing

Europe demonstrates robust adoption of titanium powder across automotive, aerospace, and medical device production.

- Germany (17.0% CAGR) leads the regional landscape with titanium applications in turbo systems, turbine blades, and surgical instruments.

- France (15.5%) continues to scale additive manufacturing for marine engineering and structural cladding, while the United Kingdom (14.1%) focuses on aerospace and orthopedic implant production using selective laser melting technologies.

European OEMs prioritize certified, high-purity titanium powders for performance reliability, supported by stringent EU material traceability frameworks.

United States — Aerospace and Defense Reinvention

The U.S. titanium powder market, expanding at 12.6% CAGR, is driven by large-scale adoption across defense, space exploration, and next-generation aircraft manufacturing. Additive manufacturing centers are incorporating spherical titanium alloys with controlled oxygen content to achieve structural precision and reduced material wastage.

U.S. investments in recycling and closed-loop titanium powder systems are reinforcing domestic sustainability goals and reducing reliance on imported feedstock.

Saudi Arabia — Emerging Titanium Cluster in the Middle East

Saudi Arabia’s titanium powder market is gaining traction under its Vision 2030 industrial diversification strategy. With rising investments in aerospace maintenance, medical manufacturing, and defense-grade metallurgy, the Kingdom is positioning itself as a regional hub for high-performance titanium materials. Establishing local powder atomization units and R&D partnerships with global suppliers is expected to enhance supply security and additive manufacturing capabilities in the Gulf region.

Market Drivers and Key Trends

1. Additive Manufacturing Expansion: Titanium’s use in 3D printing is enabling intricate geometries and lightweight parts for both aerospace and medical industries. Alloyed titanium powders now represent nearly 50% of global output.

2. Sustainability and Recycling: Growing adoption of closed-loop powder recycling and “powder-as-a-service” models is driving circularity and reducing waste in advanced manufacturing.

3. High-Performance Customization: Innovations in alloy composition and particle size control are improving powder flowability and structural integrity, opening new markets in electronics and EV manufacturing.

4. Strategic Alliances: Collaboration between powder producers, additive machine builders, and aerospace OEMs is ensuring traceable, high-quality supply chains.

Gain complete access to the report for extensive coverage of market forecasts, competitive benchmarking, and evolving industry trends! Buy Full Report: https://www.futuremarketinsights.com/checkout/23000

Challenges and Restraints

Despite its strong growth outlook, titanium powder remains cost-intensive, with high atomization energy requirements and oxidation control challenges. Price per kilogram remains higher than aluminum or steel powders, limiting adoption in low-margin industrial sectors. However, ongoing R&D in hydride–dehydride refinement and plasma atomization cost optimization is expected to narrow this gap by 2030.

Competitive Landscape

The titanium powder market features a multi-tier structure led by Tier 1 suppliers with advanced plasma atomization capabilities. These global manufacturers focus on producing high-purity, spherical titanium powders that meet aerospace and biomedical certification standards.

Tier 2 manufacturers serve automotive and industrial clients through customized alloy blends, while Tier 3 suppliers cater to research institutions and prototype development.

Companies continue to invest in regional recycling centers, powder testing labs, and alloy optimization programs to strengthen traceability and expand their additive manufacturing client base.

Recent Developments

- June 2024: A European aerospace manufacturer signed a strategic supply agreement for plasma-atomized titanium powder optimized for additive manufacturing, marking a significant milestone in closed-loop powder production.

- 2025: Ongoing collaborations in Asia and North America are accelerating deployment of powder metallurgy hubs, reinforcing global supply resilience.

Future Outlook

According to FMI, the titanium powder market’s trajectory through 2035 will be defined by aerospace scalability, medical innovation, and sustainable metallurgy. As cost efficiencies improve and alloy diversity broadens, titanium powder will transition from niche to mainstream industrial material, enabling a new era of lightweight, high-performance engineering across global markets.

Exploring Insights Across Emerging Global Markets:

Food & Beverage Industrial Disinfection and Cleaning Market: https://www.futuremarketinsights.com/reports/food-beverage-industrial-disinfection-cleaning-market

Green Coatings Market: https://www.futuremarketinsights.com/reports/green-coatings-market

Europe Aluminum Oxide Market: https://www.futuremarketinsights.com/reports/europe-aluminum-oxide-market

USA and Canada Teak Veneer Sheet Market: https://www.futuremarketinsights.com/reports/usa-canada-teak-veneer-sheet-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.