Pearl Technologies Announces New FlexSeal™ Product Line

Innovative FlexSeal design simplifies line changes improving productivity

SAVANNAH, NEW YORK, USA, November 27, 2017 /EINPresswire.com/ -- Contacts

Media

Jeff Nestel-Patt

+1.978.761.8303

jeff@jnpmarketinggroup.com

Company

Jennifer Gillette

+1.315.365.3742

jgillette@pearltechinc.com

Pearl Technologies Announces New FlexSeal™ Product Line

Innovative FlexSeal design simplifies line changes improving productivity

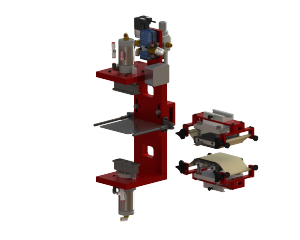

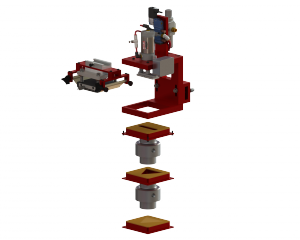

Savannah, New York – November 27, 2017 – Pearl Technologies released its new FlexSeal™ product line designed to simplify sealing line changeovers and improve productivity for a wide range of intermittent sealing applications with poly and pouch films. Based on the same design innovation as Pearl’s industry-leading Flex Unit products, the FlexSeal offer a low-cost, highly efficient sealing unit for common sealing applications such as top seal, top and bottom seal with or without center platen, and cut-seal with bottom slug removal.

"Our new FlexSeal product offering extends the same ease-of-use benefits of our Flex Unit punch technology to poly and pouch sealing production lines," said Nik Green, Senior R&D Manufacturing Engineer, Pearl Technologies. “The FlexSeal provides a fully integrated assembly available in different sizes that is easy to remove and mount on any poly or pouch bag machine."

The FlexSeal is ideal for bottom gusseting, reinforcing handle holes, strengthening drawstring bag tops and other common sealing applications. The FlexSeal assemblies are available in a variety of sizes and offer full “plug-and-play” compatibility with poly and pouch machines for easy line changeovers. The FlexSeal assemblies utilize a cartridge that comprises the sealing head, heating element and the Teflon tape unwind-rewind station. It can be disconnected or re-installed in seconds and no tools are needed.

Pearl will be showcasing its new FlexSeal at Global Pouch West, booth 23, December 5-7 in Anaheim, CA.

About Pearl Technologies, Inc.

Pearl Technologies is a leading supplier of precision converting products for the global flexible packaging and blown film industries. Pearl’s products are recognized for improving worker safety and driving greater throughput in the line delivering lower cost of ownership. Key products include a wide variety of punches, slitters and perforators, punching attachments for wicketing, handle holes, hanger holes, and venting attachments. Founded in 1985, the company is headquartered in Savannah, New York, and ships its products to customers in over 35 countries worldwide. For more information visit www.pearltechinc.com.

Jeff Nestel-Patt

JNP Marketing Group LLC

9787618303

email us here