10 Speedy Shipping Station Setup Tips

It’s time to review your operations and see where you can make your shipping process more efficient with fewer errors. Read 10 shipping station setup tips!

Find out more about our warehouse order fulfillment solutions today. Want to grow your warehouse fulfillment business? Formaspace has the right solution for your shipping stations.

AUSTIN, TEXAS, UNITED STATES, April 10, 2016 /EINPresswire.com/ -- Let's look at ways you can improve your competitiveness in the warehouse shipping room. As industry giants like Google work hard to speed up their customer order fulfillment – now delivering orders in as little as a couple hours in select urban locations — it’s time to review your own operations and see where you can make your shipping service more efficient – with fewer errors.— Formaspace

Tip 1: Avoid the temptation to try to optimize your shipping stations before you have a clear understanding of your overall operations.

Everyone has an opinion about how shipping stations should be set up — especially those who have never worked at a packing workstation! Avoid starting discussions on improving efficiency that start with what the shipping stations should look like and where the packing supplies are stored. Save that for last, after you’ve performed a comprehensive study of how your overall operations work. It may seem like this approach will take more time — and it probably will — but you’ll get better results in the end.

Tip 2: Do your research and identify any bottlenecks in your order fulfillment and material handling systems first.

There is no substitute for firsthand observation and measurement. Keep an eye out for flow problems that are causing bottlenecks before materials arrive at the shipping station. Look for specific indications of inefficiency, such as:

* Workers moving materials between different stations outside the normal flow sequence.

* Materials accumulating at the end of an automated process faster than workers can process them.

* Materials stacked on a temporary basis in different areas until they can be processed.

Tip 3: Take the time to understand and optimize the flow of your order transportation and staging.

If you uncovered indications of problems in the previous tip, it’s likely you have bottlenecks in the system. Study these issues further to find out the root cause of the problem. Pay close attention to the way your containers arrive at the shipping station. If the packer at the shipping station has to access multiple containers to get materials to complete an order, the containers are not arriving in the correct sequential order. This needs to be corrected. And if you observe the packer walking away from the shipping station to find an item, something is wrong in the staging process.

Tip 4: Identify the exact steps (in correct order) in the order fulfillment process.

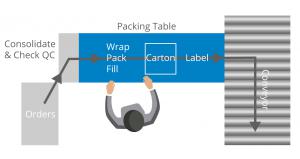

Use the results to design a straight-line flow pattern shipping station. Each warehouse shipping room set up is different, but most shipping services follow a similar workflow pattern. Generally speaking, you start with picking the order in the warehouse, consolidating the order in tubs or containers, performing a quality check on the order, and then transporting the consolidated order to the shipping station. At the shipping station, the packer will pack the order into shipping containers (boxes, envelopes, etc.), label the order and create the shipping manifest. From there, the orders are transported to the shipping dock. Take the time needed to document your operation’s exact, unique steps and keep this document up to date as you make changes. Once you’ve created documentation outlining the exact workflow steps, you can easily translate this into a design for a straight-line flow pattern shipping station.

Tip 5: Try to design out errors in your workflow by considering what happens when a mistake is made at each stage of the process.

It’s important to stamp out errors in the order fulfillment process. One way to do this is by conducting a mental exercise where you consider the impact a mistake made at each point in the line will have. Can the mistake be discovered and corrected before an incorrect, incomplete or damaged product is shipped to the customer? Ideally, you can prevent mistakes (or at least catch them) before materials reach the shipping station. If not, the packer at the shipping station is your quality assurance tester of last resort. Therefore, you need to make sure the packer can identify and correct mistakes efficiently while keeping the line moving. Make sure you provide enough workspace for the packer to correct situations without a lot of fuss and bother when he or she is presented with the wrong SKU, the wrong count, the wrong product color, etc. To accomplish this, plan out the error correction sequence in advance. Make sure there is enough physical space at the shipping station to set aside the incorrect materials and replace them with the corrected ones. This includes provisioning enough space to make the correction; for example, there might need to be space on the shipping table for two boxes at the same time, the incorrect one and the corrected one.

Tip 6: Make sure your shipping station has all the equipment and automation tools, packing supplies and personal items needed to do the job.

Read more...

Mehmet Atesoglu

Formaspace

8002511505

email us here